PT Duct an effective method for corrosion protection of internal post tensioning tendons; It provides corrosion resistance by complete encapsulation of the tensions. The usage of plastic ducts ad corrosion protection started in the early 1990's initially HDPE ducts were used then it evolved based on projects actual experiences where new designs and material I.E Polypropylene (PP) was used to achieve better performance.

PP Ducts for Post tensioning application

All ducts are produce according to the following standards

- ♦ AASHTI LRFD Bridge Constructing Specification for internal, external . HDPE and PP ducts.

- ♦ Raw material classifieds by ASTM D41010, ASTM D3350

| APPLICATIONS |

|---|

| Corrosion Protection for Post Tensioning Strands for |

| Flyovers and bridges |

| Nuclear containments |

| Offshore platforms |

| Via dusts |

| Under passes |

| Tunnels |

| Structures exposed to high humidity |

| Waste water treatment plants |

| Acid tanks |

| Silos |

| ADVANTAGES |

|---|

| Better corrosion protection |

| Improved tendon fatigue performance |

| Reduced tendon friction |

| Reduce construction time with the help of post-tensioning slabs(Flat Ducts) |

Couplers for PT Ducts

Description

The couplers are manufactured to suit our PT Ducts,

Raw material

The ducts are manufactured from polypropylene resin (PP)

| ADVANTAGES |

|---|

| Flyover& Bridges, Offshore platforms structures exposed to high humidity |

| Under passes, Tunnels |

Geometrical Properties

| Suitable to KAI PP PT Duct; Nominal Size |

Nominal outside diameter (mm) |

Nominnal thickness (mm) |

Nominal length (mm) |

|---|---|---|---|

| 76 | 101 | 5.0 | 150 |

| 85 | 111 | 5.5 | 150 |

| 100 | 126 | 5.0 | 150 |

| 115 | 142 | 4.5 | 200 |

| 130 | 161 | 5.5 | 200 |

| 144 | 181 | 5.5 | 200 |

Physical Properties

| Description | Test method | Limits | Unit |

|---|---|---|---|

| Density@23C (kg/m3) | ASTM D792 | 900 | Kg/m3 |

| Deflection Temperature at 455KPa | ASTM D648 | 80-120 | C |

| lzod impact @23C | ASTM D256 | 300-700 | J/m |

| Flexural mmodules @ 103mm/min | ASTM D790 | 750-1.000 | MPa |

| 130 | 161 | 5.5 | 200 |

| Tensile stress at yield @50mm/min | ASTM D638 | 20-30 | MPa |

Round Polypropylene PT Duct

| Diameter Size | Inside Diameter of the dust mm |

Outside Diameter of the duct mm |

T-Wall thickness mm |

Length | Jointing | Packing Local Overseas |

|

|---|---|---|---|---|---|---|---|

| 76 | 74+1.5 | 90+-1.5 | 2.5+-0.25 | 6m+-1% and 12m+-% |

|

11.8ML Loose |

|

| 85 | 85±1.5 | 101±1.5 | 2.5±0.25 | 12m x 25nos | |||

| 100 | 99+1.5 | 114+-1.5 | 3.0+-0.25 | ||||

| 115 | 113+-1.5 | 133+-1.5 | 3.0+-0.25 | 12m x 20nos | |||

| 144 | 143+1.5 | 169+-1.5 | 3.25+-0.25 | 12m x 10nos | |||

| Raw material | Color | ||||||

| Polypropylene | white | ||||||

| Description | Test Method | Value | Unit |

|---|---|---|---|

| Tensile Strength at yield | ASTM D638 | 20-30 | MPa |

| Deflection Temperature at 455Ka | ASTM D648 | 80-120 | *c |

Round polypropylene PT Duct

Sectional Elevation View "D" "D"

Pt Duct Round

Dn 76

Pt Duct Round

Dn 85

Pt Duct Round

Dn 100

Pt Duct Round

Dn 115

Pt Duct Round

Dn 130

Pt Duct Round

Dn 144

FLAT/OVAL POLYPROPYLENE PT Duct

| Diameter size | Inside Diameter of duct mm |

Outside Diameter of the duct mm |

t- Wall thickness

mm |

Length | Jointing | Packing | |

|---|---|---|---|---|---|---|---|

| 73*22 | 72+-1.0 | 19+-1.0 | 88+-1.0/35+-1.0 | 2.0+- 0.25/2.0+-.025 | 6m+-1% and 12m+-!%12+-1% |

Socket coupler | Coil 200m |

| 90/22 | 86+-1.0 | 190+-1 | 102+-1.0/35+-1.0 | 2.0+-0.25 | Shrink sleeve Butt welding | ||

| Raw material | Color | ||||||

| Polypropylene | white | ||||||

Physical properties

| Description | Test method | Value | Unit |

|---|---|---|---|

| Tensile Strength at yield | ASTM D638 | 20-30 | MPa |

| Deflection Temperature at 445KPa | ASTM D648 | 80-120 | *C |

FLAT/OVAL POLYPROPYLENE PT Duct

Pt Duct Flat

Dn 73x22

Pt Duct Flat

Dn 90x22

Main Projects

| Project name | Country | Supply Duration | PT Products |

|---|---|---|---|

| RA/166 Jahra Road |

Kuwait | 2014 | --PP Internal Duct |

| RA/213 Jamal Abdul Nasser Road |

Kuwait | 2015 | --PP Internal Duct |

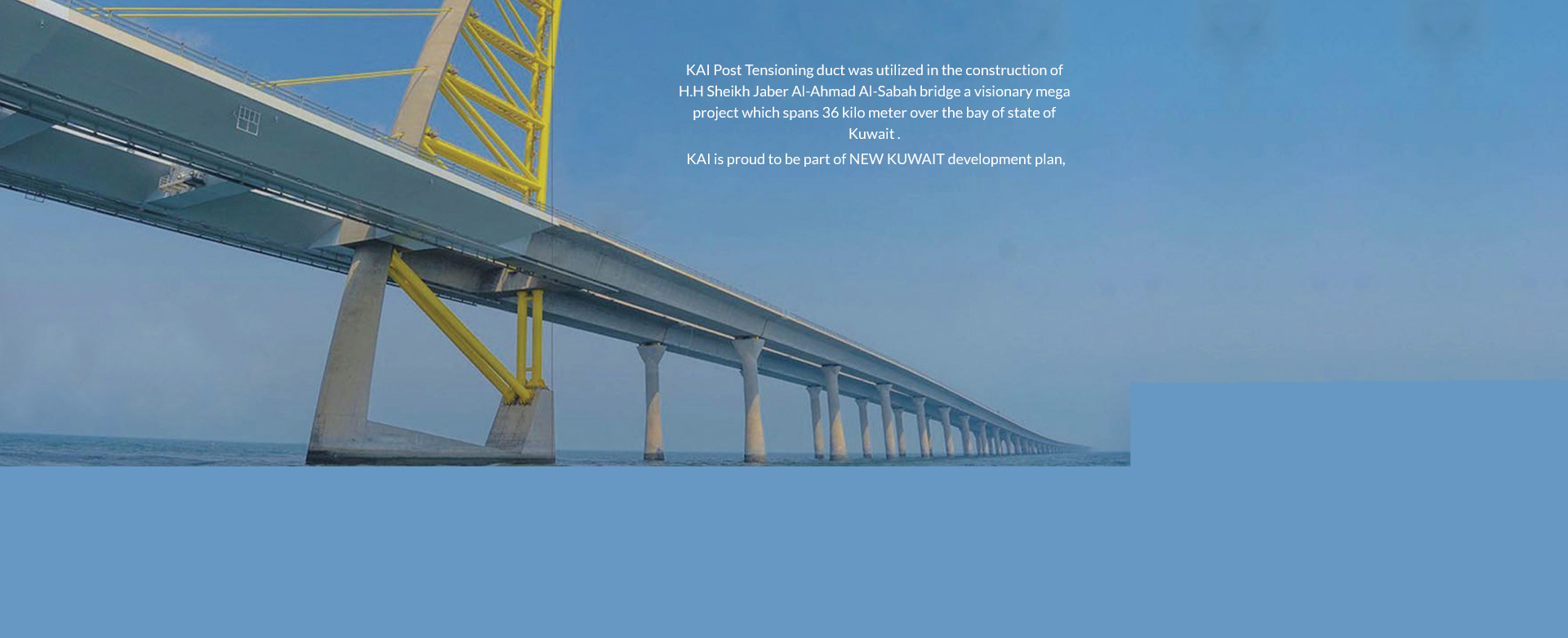

| RA/140 Jaber Al Ahmad Al Sabah Causeway |

Kuwait | 2015 | --PP Internal Duct |

| RA/211 Jaber Al Ahmad Road Crossing |

Kuwait | 2015 | --PP Internal Duct |

| Metro Project | K.S.A | 2015 | --PP Internal Duct |

| RA/222 Al-Bedaa Road |

Kuwait | 2017 | --PP Internal Duct |

| Mutlaa Phase | Kuwait | 2018 | --PP Internal Duct |

| RA/217 Development of Nuwaseeb Road |

Kuwait | 2018 | --PP Internal Duct |

| RA/167 Jamal Abdul Nasser Road |

Kuwait | 2018 | --PP Internal Duct |

| RA/225 Saad Al-Abdullah Road |

Kuwait | 2018 | --PP Internal Duct |

| Zour Al-Zour Colander |

Kuwait | 2018 | --PP Internal Duct |

| RA/126 Development of south Al-Surra Road |

Kuwait | 2018 | --PP Internal Duct |

| RA/259 Al-Salmi & Kabad |

Kuwait | 2019 | --PP Internal Duct |